Flange Joint Assembly

It is important that the flange alignment is maintained before and during the tightening process to assist in maintaining joint integrity.

Flange integrity requires the minimum amount of gasket compression and even compression around the gasket surface.

Correct compression of the gasket is achieved by equal bolt loading of the flanges.

Correct vertical and horizontal alignment is maintained.

Ensure no cross axial stresses are seen in the pipework.

All the bolts should be ‘nipped’ or ‘snugged’ up evenly and the correct tightening procedure applied.

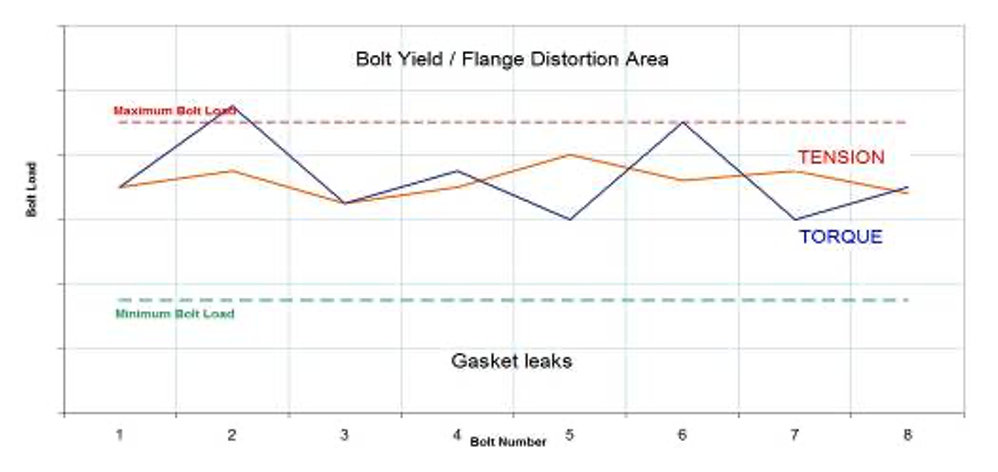

The different bolt tightening methods can affect the reliability and accuracy of residual bolt load.

Formula for Residual Bolt Loading:

Applied Torque minus Friction Losses = Residual Bolt Load

Applied Force minus Load Transfer = Residual Bolt Load

The friction losses during torque tightening can be extremely high.

The friction losses during tensioning are so low that we do not consider them.

Additional methods can be used in conjunction with torque tightening i.e. ultrasonic’s measurement and bolt load monitoring.

Torque tightening procedures are used more widely on small diameter, short length bolting applications and when the bolt stress required is close to yield.

It is important that the correct torque value are utilised for each application.

The residual bolt load required for the tightening procedure must be correctly aimed at the bolt load range.

Only use the correct applied loads specified for the equipment being used.

All equipment used must be suitable for the job specifications.